Buy VisualCAM for SolidWorks Software

October 2025 Sale!

Limited time: 5% discount on all products! Ends November 1.

VisualCAM for SolidWorks 2010-2018 x32+x64

| Version | Price & Buy |

|---|---|

| 2018 7.0.426 | |

| 2017 6.0.507 |

What Is VisualCAM for SolidWorks?

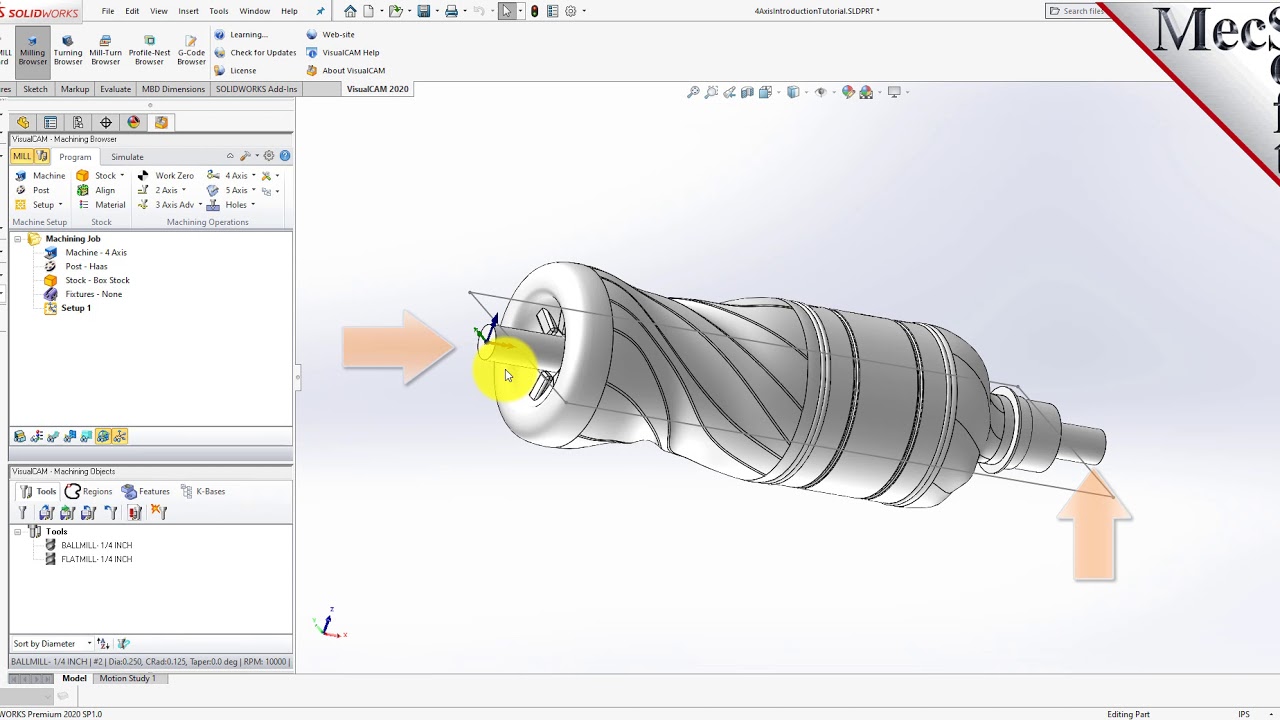

VisualCAM for SolidWorks is a Gold-certified CAM plugin that operates directly inside the SolidWorks environment, transforming CAD designs into CNC toolpaths without switching applications. The software maintains a single-window workflow where engineers and machinists create manufacturing programs using the same interface they already know from their design work.

This integration eliminates the typical handoff delays between design and manufacturing departments. When design changes happen, there's no need to export files, switch programs, or worry about compatibility issues. The Gold certification from SolidWorks ensures ongoing compatibility with new releases and reliable performance across updates.

Manufacturing shops using SolidWorks for design can now handle both CAD and CAM operations from a single platform. This approach reduces the software learning curve for teams already familiar with the SolidWorks interface while maintaining design integrity throughout the manufacturing process.

How Does VisualCAM Streamline Manufacturing Workflows?

The software tackles two major bottlenecks in CNC programming: time-consuming manual toolpath creation and the complexity of multi-step workflows.

Seamless SolidWorks Integration

Gold Partner status with SolidWorks means VisualCAM accesses native geometry directly without file conversion. Design features remain fully associative—when a SolidWorks model updates, the corresponding toolpaths can regenerate automatically to reflect those changes. This associativity prevents the common problem of machining outdated part revisions, a costly mistake in production environments.

The plugin integrates with SolidWorks' PropertyManager and FeatureManager design tree, giving users familiar interface elements rather than forcing them to learn completely new workflows. File format support extends beyond SolidWorks native files to include DXF, DWG, IGES, STEP, and STL formats, making it versatile for shops working with models from various CAD systems.

Automated Toolpath Generation

Automatic Feature Detection (AFD) scans solid models and identifies machinable features like holes, pockets, and bosses without manual selection. Once features are detected, Automatic Feature Machining (AFM) applies pre-defined machining strategies from a knowledge base, generating complete toolpaths in minutes rather than hours.

The knowledge base contains proven cutting strategies for common feature types. Shops can customize these strategies based on their specific machine capabilities and materials, then reuse them across multiple projects. This automation doesn't just save time—it standardizes machining approaches across different programmers, ensuring consistent results.

What Are the Key Benefits of VisualCAM?

- Reduced Programming Time: Automation features handle repetitive tasks like feature recognition and toolpath generation, cutting manual programming hours significantly

- Material Waste Prevention: The True Shape Nesting module arranges multiple parts on sheet stock to maximize material usage and minimize scrap

- Error Detection Before Machining: Real-time toolpath simulation visualizes material removal and identifies potential collisions, tool clearance issues, or programming errors before any metal is cut

- Multi-Axis Flexibility: Support for 2½, 3, 4, and 5-axis machining operations means one software package handles simple drilling operations through complex simultaneous 5-axis surfacing

Simulation capabilities deserve particular attention. Watching the virtual cutting process reveals problems that might otherwise damage expensive workpieces or CNC equipment. The cut material visualization shows exactly how much stock remains at any point in the machining sequence.

What Applications and Industries Use VisualCAM?

The software serves diverse manufacturing segments, each with specific requirements that VisualCAM addresses through specialized features.

Manufacturing Applications

| Application | Key Capabilities | Business Value |

|---|---|---|

| Mold and Die Making | Multi-surface machining, Z-level roughing, pencil tracing for tight corners | Handles complex cavity geometries with tight tolerances required for injection molds |

| Rapid Prototyping | Direct import from CAD models, automatic feature detection, quick toolpath generation | Accelerates time from design concept to physical prototype for testing and validation |

| Aerospace Components | 5-axis continuous machining, precision toolpath control, verification simulation | Meets strict tolerance and surface finish requirements for flight-critical parts |

| Automotive Tooling | High-speed machining strategies, large component handling, efficient roughing | Produces stamping dies and fixtures with optimized cycle times |

Specialized Applications

Beyond traditional machining, VisualCAM includes capabilities for niche applications. The VisualART module converts bitmap images into machinable 3D geometry, enabling sign makers and engravers to transform logos, artwork, and text into toolpaths for decorative work. Woodworking shops use these same capabilities for carved furniture components and architectural millwork.

The Profile-NEST module serves sheet cutting operations, nesting 2D profiles efficiently for plasma, laser, or waterjet cutting. This extends VisualCAM's utility beyond traditional milling into fabrication workflows where material optimization directly impacts profitability.

How Does VisualCAM Integrate With Your Existing Tools?

Manufacturing environments rely on diverse equipment and software ecosystems. VisualCAM accommodates this reality through comprehensive compatibility features.

File Format Support

Native SolidWorks file handling (.sldprt) provides the tightest integration, but shops working with mixed CAD systems benefit from support for industry-standard formats. STEP and IGES files import from virtually any CAD system, while STL support enables working with scanned meshes or topology-optimized designs. DXF and DWG import handles 2D profiles for profiling and nesting operations.

The software maintains model associativity where possible, meaning changes to source geometry can flow through to manufacturing programs. This bidirectional relationship between design and manufacturing keeps production data current as designs evolve.

CNC Machine Compatibility

Post-processor libraries include configurations for hundreds of CNC machine controllers from manufacturers like Haas, Fanuc, Mazak, and DMG Mori. These post processors convert VisualCAM's generic toolpath data into machine-specific G-code tailored to each controller's syntax and capabilities.

For shops with custom or less common machines, programmable post processors use Python scripting to create customized output. This flexibility ensures VisualCAM adapts to existing equipment rather than forcing shops to work around software limitations.

Why Choose VisualCAM for Your Shop?

Gold Certification Assurance

Official SolidWorks Gold Partner status guarantees reliable integration, ongoing compatibility updates, and adherence to SolidWorks API standards.

Proven Multi-Industry Performance

Deployment across mold making, aerospace, automotive tooling, sign making, and woodworking industries demonstrates versatility and reliability.

Comprehensive Automation Tools

AFD, AFM, and True Shape Nesting reduce manual work while improving consistency and material utilization.

Small to Mid-Market Focus

Designed specifically for shops that need professional CAM capabilities without enterprise complexity or investment.

The combination of automation, simulation, and integration addresses the core challenges manufacturing shops face: reducing programming time, preventing costly errors, and maintaining efficient workflows. Shops operating SolidWorks for design gain the most immediate benefit, since the interface familiarity and data continuity eliminate traditional CAD-to-CAM friction points.

Frequently Asked Questions

Is VisualCAM Easy to Learn for SolidWorks Users?

Existing SolidWorks users find VisualCAM intuitive because it uses familiar interface elements like PropertyManager panels and the FeatureManager design tree. The software operates within the same window environment users already know, reducing the cognitive load of learning entirely new navigation patterns.

What File Formats Does VisualCAM Support?

The software handles native SolidWorks files (.sldprt) plus industry-standard formats including STEP, IGES, STL, DXF, and DWG. This broad compatibility enables working with models from virtually any CAD system while maintaining geometry integrity.

Can VisualCAM Handle Multi-Axis Machining?

Full support for 2½, 3, 4, and 5-axis operations enables everything from simple drilling and pocketing through complex simultaneous 5-axis surface machining. The same software environment handles both simple and sophisticated machining requirements.