Purchase VisualCAM for SolidWorks Software

January Sale!

Limited time: 5% discount on all products! Ends February 1.

VisualCAM for SolidWorks 2010-2018 x32+x64

| Version | Price & Buy |

|---|---|

| 2018 7.0.426 | |

| 2017 6.0.507 |

What is VisualCAM for SolidWorks?

VisualCAM for SolidWorks is a Gold-certified CAM (Computer Aided Manufacturing) software developed by MecSoft Corporation that integrates directly into SolidWorks. This plugin transforms SolidWorks models into CNC toolpaths for milling, turning, and multi-axis machining operations.

Designed for small to mid-sized manufacturers, VisualCAM provides an affordable yet powerful solution for generating G-code without leaving the SolidWorks environment. The software serves machine shops, tool and die makers, mold manufacturers, and independent machinists who need efficient CAM programming capabilities within their existing SolidWorks workflow.

Why Buy VisualCAM for SolidWorks from Prosoftstore?

How Much Does VisualCAM for SolidWorks Cost?

Official VisualCAM pricing typically starts around $595 for entry-level MILL Xpress configurations and can scale to $5,000+ for Professional and premium multi-axis packages, depending on the selected modules, number of seats, maintenance, and support options. Pricing is often quote-based through resellers, and may vary by region and bundle configuration.

VisualCAM for SolidWorks Discount Price at Prosoftstore

We offer permanent activation with one-time purchase from $55 to $65 — professional CAM programming solution for machine shops, mold makers, independent machinists, and home CNC operators without subscription fees. Full functionality included for multi-axis milling, CNC turning operations, mold making, and prototype manufacturing.

Single payment, lifetime access, no hidden costs or mandatory renewals. Suitable for personal projects, skill development, and independent or small-shop machining work where you need SolidWorks-integrated CAM without ongoing vendor subscription commitments.

What Does VisualCAM Do?

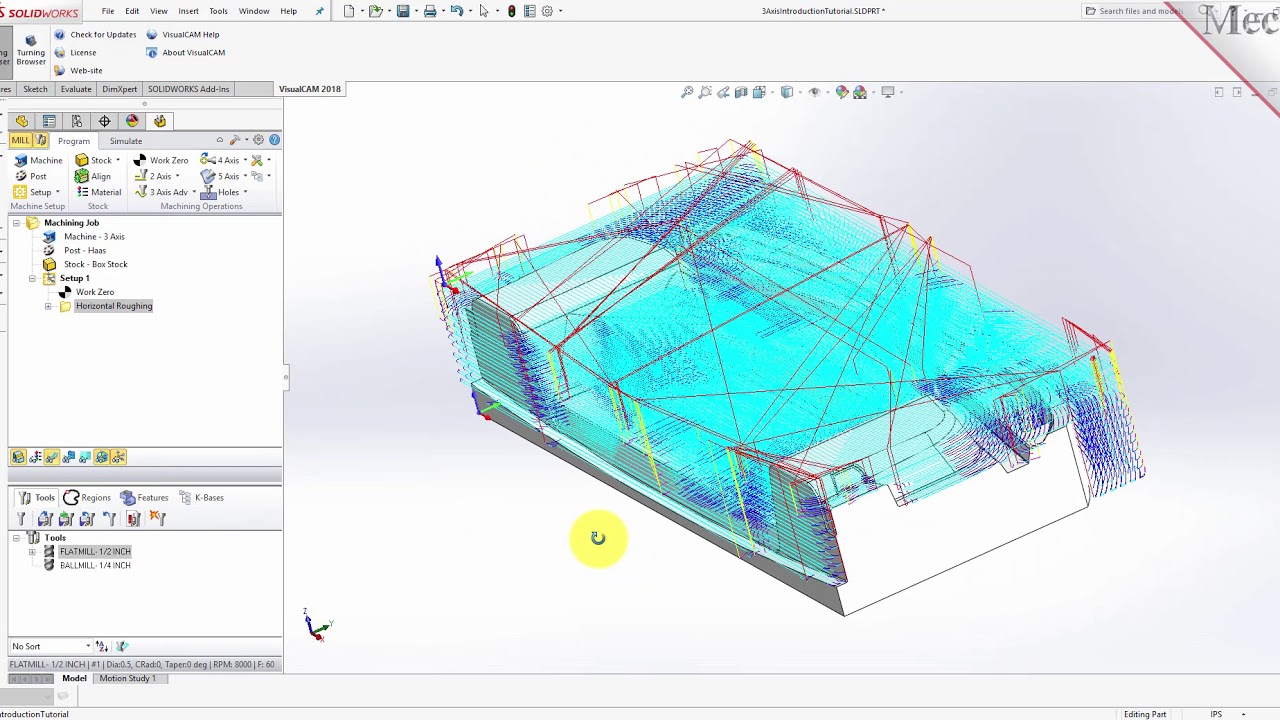

VisualCAM generates CNC toolpaths directly from SolidWorks models, supporting various machining operations from basic 2.5-axis milling to advanced 5-axis simultaneous cutting. The software bridges the gap between CAD design and physical manufacturing by creating machine-readable G-code instructions.

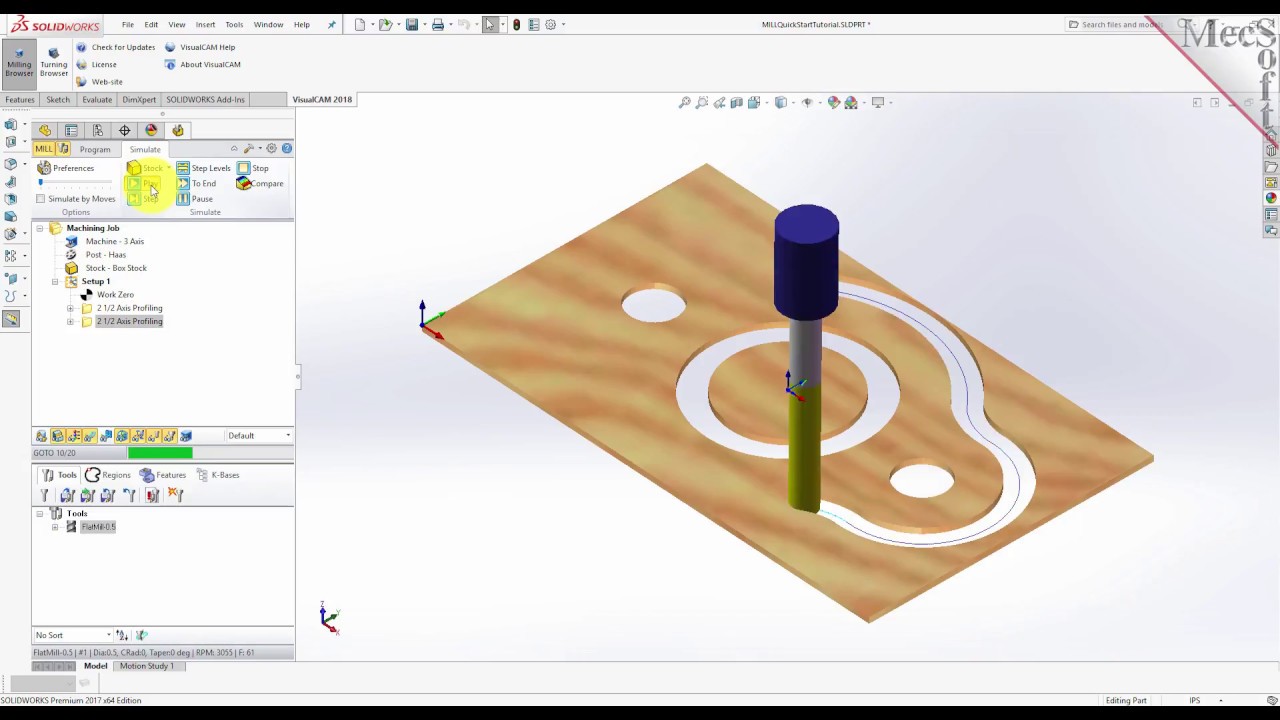

- 2.5-Axis to 5-Axis Milling: Supports face milling, pocketing, profiling, contouring, drilling, and simultaneous 5-axis machining with full kinematic control.

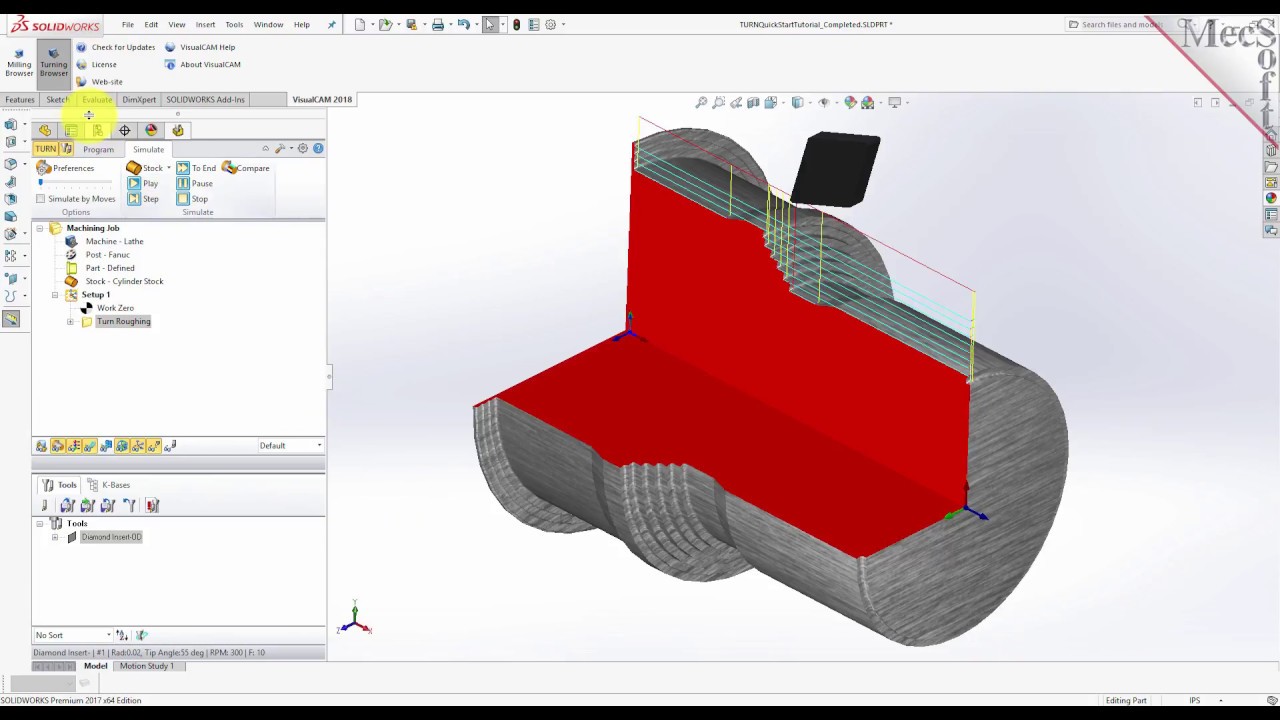

- 2-Axis Turning Operations: Generates toolpaths for roughing, finishing, grooving, threading, and parting-off operations on lathe machines with automatic tool selection.

- Adaptive Roughing: Automatically calculates efficient material removal strategies that maintain constant tool engagement and reduce machining time.

- Collision Detection: Simulates tool holder and machine movements to identify potential collisions before sending code to the CNC machine.

- Nesting Module: Optimizes material usage by automatically arranging multiple parts on sheet stock for plasma, laser, or router cutting.

- Post Processor Generator: Includes customizable Python-based post processors to format G-code for specific CNC machines and controllers.

- Toolpath Simulation: Provides visual verification of cutting operations with material removal animation and part-versus-stock comparison.

- Integrated Workflow: Maintains parametric links to SolidWorks geometry, automatically updating toolpaths when design changes occur.

VisualCAM vs VisualMILL

VisualCAM is specifically designed as a SolidWorks plugin with tight integration into the SolidWorks interface and file structure. VisualMILL is MecSoft's standalone milling solution that works independently without requiring SolidWorks. Choose VisualCAM when you work primarily in SolidWorks and need seamless model-to-toolpath workflow.

Where and Who Uses VisualCAM?

| Industry/Profession | Application |

|---|---|

| Mold and Die Makers | Programming complex cavity and core machining for injection molds with multi-axis finishing toolpaths |

| Contract Machine Shops | Generating toolpaths for custom parts across milling and turning operations with quick turnaround requirements |

| Prototype Manufacturers | Creating one-off and short-run production parts directly from SolidWorks design files without file conversion |

| Aerospace Component Fabricators | Programming 5-axis machining for turbine blades, structural brackets, and precision aluminum components |

| Tool and Fixture Builders | Producing jigs, fixtures, and workholding devices with precise pocket milling and drilling operations |

| Technical Schools and Training Centers | Teaching CNC programming fundamentals and CAM workflow integration to students and technicians |

How Can You Use VisualCAM at Home?

VisualCAM enables personal CNC projects and professional skill development for home workshops equipped with desktop mills or lathes. Whether building technical skills or producing functional parts, the software provides full professional capabilities for independent work.

- For beginners: Learning fundamental CNC programming by creating simple 2.5-axis toolpaths for aluminum or plastic parts on desktop milling machines.

- For beginners: Practicing basic turning operations and thread cutting using lathe simulation before running actual machine code.

- For advanced users: Programming custom firearm components, knife handles, or precision mechanical assemblies for personal gunsmithing or hobbyist projects.

- For advanced users: Developing prototype parts for small-scale product development or Etsy-style manufacturing businesses using multi-axis milling.

- For advanced users: Creating molds for resin casting projects, including miniature figures, jewelry, or decorative items with detailed 3D contouring.

- For advanced users: Machining replacement parts for vintage machinery, automotive restoration, or RC vehicles when original components are unavailable.

- For advanced users: Building advanced CNC programming skills through contract work or freelance machining services operated from home shop environments.

What’s New in VisualCAM 2018 for SolidWorks?

- Automatic feature detection and automatic feature machining for 2½-axis features across entire parts, including pockets, holes, and fillets.

- Improved 3-axis horizontal roughing and finishing with better cut ordering, containment controls, and more robust Z-level processing.

- New 4-axis programming options in the Premium configuration that allow 4-axis machining using continuous 5-axis toolpath methods.

- Drilling enhancements such as new peck tapping operations and more efficient simulation of deep drill cycles without unnecessary clearance retracts.

- Simulation and post-processing improvements, including tool holder collision flagging in the toolpath editor and expanded post variables for advanced controllers.